A manual transmission is a complex system of components like gears, shafts, and synchronizers, enabling smooth gear shifting and driver control over torque and speed ratios.

1.1 Overview of Manual Transmissions

A manual transmission is a mechanical system that enables vehicles to adjust speed and torque by manually shifting gears. It consists of a complex assembly of components like gears, shafts, and synchronizers, working in harmony to provide smooth transitions. Drivers control the system via a clutch pedal and gear lever, engaging and disengaging gears to balance power delivery and speed. This design offers precision and efficiency, making it a preferred choice for many drivers.

1.2 Importance of Manual Transmission Components

Manual transmission components are essential for enabling smooth gear shifts and efficient power transfer. Each part, from the clutch to the synchronizers, plays a critical role in maintaining control and performance. Proper functioning ensures optimal torque delivery, reduces wear on engine components, and enhances overall driving efficiency, making these components vital for both functionality and longevity of the vehicle.

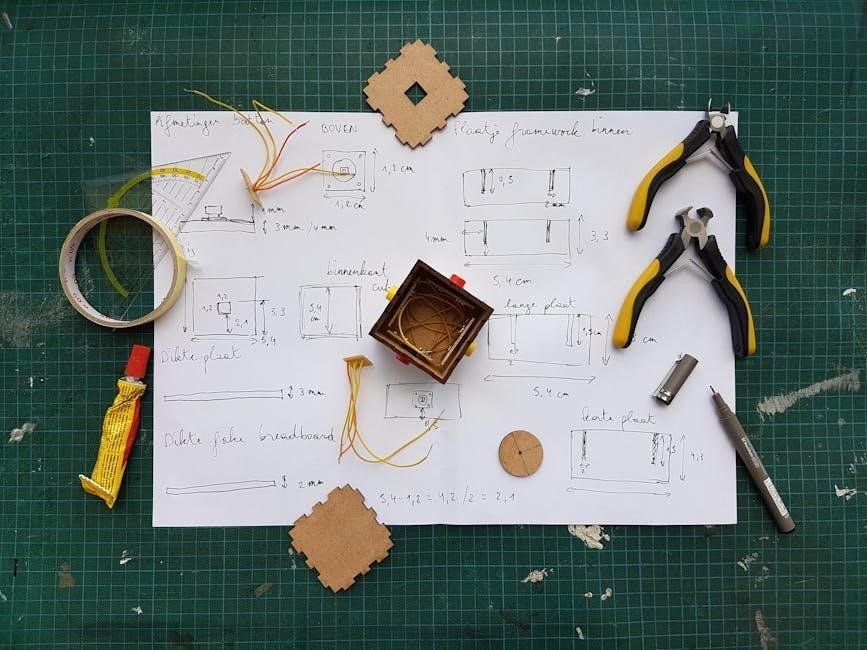

Major Components of a Manual Transmission

The major components include gears, shafts, the clutch, synchronizers, and the gear lever, all working together to enable manual gear shifts and efficient power transmission.

2.1 Clutch and Its Function

The clutch is a critical component that connects and disconnects the engine from the transmission, enabling smooth gear shifts; It consists of a clutch disc, pressure plate, and flywheel. When the driver presses the clutch pedal, it disengages engine power, allowing manual transmission to shift gears without grinding. This mechanism ensures efficient power transfer and control during driving.

2.2 Gears and Their Types

Gears are toothed wheels that transmit power and alter speed or torque. In manual transmissions, gears come in types such as spur, helical, and bevel gears, each designed for specific applications. Spur gears are simple with straight teeth, while helical gears have angled teeth for smoother operation. Bevel gears allow power transfer at angles, ensuring efficient and precise gear engagement.

2.3 Shafts (Input, Output, and Layshaft)

Manual transmissions rely on three key shafts: the input shaft, output shaft, and layshaft. The input shaft connects to the clutch and engine, transferring power into the transmission. The output shaft delivers torque to the drivetrain. The layshaft acts as an intermediate, carrying gears and facilitating power transfer between the input and output shafts, ensuring smooth and efficient operation.

2.4 Synchronizers and Their Role

Synchronizers are critical components in manual transmissions, ensuring smooth and precise gear engagement. They function by equalizing the speed of the collar and gear before meshing, reducing wear and tear. By creating frictional contact, synchronizers allow seamless transitions between gears, minimizing noise and effort required during shifting, thereby enhancing overall driving comfort and system durability.

2.5 Gear Lever and Shifter Fork

The gear lever, connected to the shifter fork, translates the driver’s input into precise gear shifts; The shifter fork moves the collar along the output shaft, engaging the desired gear. This mechanical linkage ensures smooth transitions by aligning the collar with the correct gear, enabling efficient and controlled power delivery through manual operation.

The Clutch System in Detail

The clutch system, comprising the clutch disc, pressure plate, and flywheel, facilitates smooth engagement and disengagement of the engine with the transmission, enabling precise gear shifts.

3.1 Clutch Disc and Pressure Plate

The clutch disc, a friction-lined component, is sandwiched between the flywheel and pressure plate. The pressure plate, driven by springs, applies force to engage the disc with the flywheel, enabling torque transfer. When the clutch pedal is pressed, the pressure plate releases, disengaging the engine from the transmission, allowing smooth gear shifts. This mechanism is crucial for manual transmission operation.

3.2 Flywheel and Its Interaction with the Clutch

The flywheel, a heavy circular component mounted on the engine’s crankshaft, stores rotational energy. Its smooth surface interfaces with the clutch disc, enabling torque transfer when the clutch engages. The flywheel’s inertia ensures engine smoothness, while its interaction with the clutch allows seamless disengagement during gear shifts, preventing engine stall and ensuring efficient power delivery to the transmission.

3.3 Hydraulic or Mechanical Clutch Linkage

The clutch linkage connects the pedal to the clutch assembly, enabling disengagement. Hydraulic systems use fluid pressure for smooth, consistent actuation, while mechanical linkages rely on cables or rods. Both systems ensure precise control, allowing drivers to engage and disengage the clutch smoothly, essential for seamless gear shifts and efficient power transfer from the engine to the manual transmission.

Gear Types and Their Applications

Gears in manual transmissions include spur, helical, bevel, and reverse gears, each designed for specific torque, speed, and noise reduction requirements in various driving conditions.

4.1 Spur Gears

Spur gears, featuring straight-cut teeth, are commonly used in manual transmissions for their simplicity and durability. They are typically found in older sliding mesh gearboxes, providing reliable torque transmission but often generating more noise compared to helical or bevel gears. Their straightforward design makes them easier to manufacture and maintain, though less refined in operation.

4.2 Helical Gears

Helical gears are an evolution of spur gears, featuring angular-cut teeth that reduce noise and vibration. They are widely used in manual transmissions for smoother operation. Their design allows for gradual engagement, enhancing durability and performance. Helical gears are preferred in modern transmissions due to their quieter operation and ability to handle higher torque loads efficiently, making them a superior choice over traditional spur gears.

4.3 Bevel Gears

Bevel gears feature a conical shape with angular-cut teeth, enabling them to change the direction of rotation between intersecting shafts; They are commonly used in manual transmissions, particularly in differential systems, where their unique design allows for smooth power redirection. Bevel gears are durable and efficient but more complex to manufacture, making them a preferred choice for applications requiring precise angular power transmission.

4.4 Reverse Gear Mechanism

The reverse gear mechanism is a small gear mounted on the layshaft, designed to reverse the rotation of the output shaft. When engaged, it allows the vehicle to move backward by altering the direction of power flow. This mechanism is essential for enabling reverse operation in manual transmissions, providing the necessary functionality for driving in reverse gear.

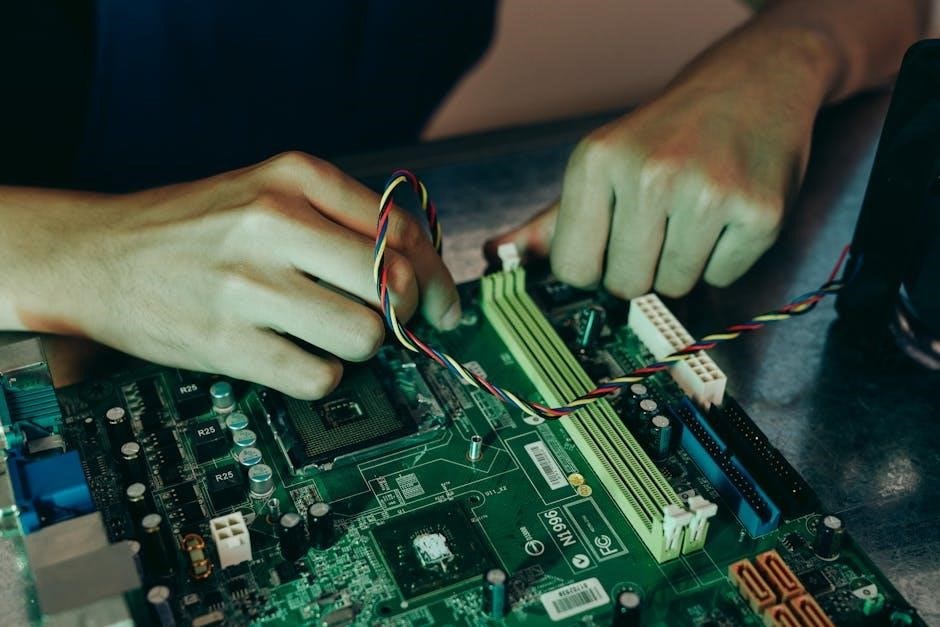

Shaft Functions and Interactions

The input, output, and layshafts work together to transmit power and adjust gear ratios. Their coordinated interaction ensures smooth power delivery and efficient gear shifting.

5.1 Input Shaft (Clutch Shaft)

The input shaft, also known as the clutch shaft, is responsible for receiving power from the engine via the clutch. It transfers this power to the layshaft, where gear ratios are adjusted. The input shaft is splined to accommodate the clutch disc and is typically mounted parallel to the layshaft and main shaft.

5.2 Output Shaft (Main Shaft)

The output shaft, or main shaft, carries the final gear ratio and transmits power to the driveshaft. Mounted parallel to the input shaft, it features gears that mesh with the layshaft. Its rotation determines vehicle speed and torque delivery. The main shaft’s gears are selected by the collar, ensuring proper power transmission based on the driver’s gear selection.

5.3 Layshaft (Countershaft)

The layshaft, or countershaft, acts as an intermediate shaft between the input and output shafts. It is mounted parallel to the main shaft and carries gears that mesh with those on the input shaft. The layshaft’s gears rotate freely until engaged by the collar, allowing the transmission to deliver the correct speed and torque ratio to the output shaft during gear shifts.

The Shifting Mechanism

The shifting mechanism enables gear changes through the gear lever and clutch, using synchronizers to match gear speeds, ensuring smooth transitions between gears.

6.1 Gear Lever and Linkage System

The gear lever and linkage system connect the driver’s input to the transmission, enabling precise gear selection. The lever operates a mechanical linkage, including rods and joints, to engage gears. This system translates the driver’s movements into gear shifts, ensuring smooth transitions between gears. The linkage system is essential for maintaining control and synchronization during shifting, providing a direct connection between the driver and the transmission.

6.2 Shifter Fork and Its Function

The shifter fork is a critical component in the manual transmission system, responsible for engaging and disengaging gears. It moves the collar along the output shaft, aligning it with the desired gear. The fork’s precise movement ensures smooth gear transitions, preventing grinding or misalignment. Its function is integral to the shifting mechanism, enabling accurate gear selection and maintaining transmission efficiency.

6.3 Synchronizer Rings and Their Operation

Synchronizer rings play a vital role in manual transmissions by facilitating smooth gear transitions. They engage with the collar and gear, ensuring rotational speed alignment. By creating frictional contact, they synchronize the shaft and gear speeds, allowing precise mechanical connection. This mechanism prevents grinding and enables seamless shifting, enhancing overall transmission efficiency and driver control during gear changes.

Types of Manual Transmissions

Manual transmissions are categorized into sliding mesh, constant mesh, and synchromesh types, each evolving to offer smoother shifting and improved efficiency over predecessors.

7.1 Sliding Mesh Transmission

The sliding mesh transmission is the oldest type, where gears slide along the main shaft to mesh with those on the layshaft. It requires double-declutching, making shifting noisy and harsh. This system lacks synchronization, leading to rough engagements and wear. It was commonly used in early vehicles, typically with up to three speeds, before being replaced by more refined designs like constant mesh and synchromesh transmissions.

7.2 Constant Mesh Transmission

The constant mesh transmission improves upon the sliding mesh by keeping gears in constant engagement. Dog clutches select the appropriate gear, eliminating double-declutching. Helical or bevel gears reduce noise compared to spur gears. However, the system requires precise alignment and results in higher wear on dog clutches due to speed differences between shafts. It was a step toward smoother shifting but still less refined than synchromesh transmissions.

7.3 Synchromesh Transmission

Synchromesh transmissions offer smoother and quieter operation by using synchronizers to match gear and shaft speeds before engagement. This eliminates the need for double-declutching, making shifting easier and less wear-prone. Synchromesh devices frictionally align components, enabling seamless transitions. Lubrication is crucial to prevent wear, making this system the most common and reliable choice in modern vehicles for efficient and driver-friendly performance.

Applications of Manual Transmissions

Manual transmissions are widely used in heavy vehicles, motorcycles, racing cars, and commercial vehicles, offering cost-effectiveness and performance advantages in various driving conditions.

8.1 Use in Heavy Vehicles

Heavy vehicles, such as trucks and loaders, predominantly use manual transmissions due to their durability and ability to handle high torque demands. This setup provides better control for hauling heavy loads and navigating challenging terrain, making manual transmissions a reliable choice for industrial and construction applications where strength and precision are critical.

8.2 Application in Motorcycles

Motorcycles widely use manual transmissions, typically featuring 4- to 6-speed gearboxes. These systems provide precise control over power delivery, enhancing acceleration and maneuverability. The compact design of motorcycle manual transmissions allows for efficient weight distribution and improved handling, making them ideal for both daily commuting and high-performance racing environments.

8.3 Racing and High-Performance Vehicles

Manual transmissions are essential in racing and high-performance vehicles due to their quick response and precise control. These systems often feature close-ratio gears and lightweight components, optimized for rapid shifting. The mechanical efficiency and direct driver engagement of manual transmissions enable faster lap times and superior performance in competitive racing environments.

8.4 Commercial Vehicles

Manual transmissions are widely used in commercial vehicles like trucks and loaders due to their durability and cost-effectiveness. These systems provide the necessary torque and control for heavy-duty applications, making them ideal for hauling large loads. The simplicity and reliability of manual transmissions reduce maintenance costs, ensuring uninterrupted operation in demanding work environments.

Common Issues and Maintenance

Clutch wear, gear grinding, and synchronizer issues are common problems. Regular fluid checks, component inspections, and timely repairs help maintain smooth operation and prevent major overhauls.

9.1 Troubleshooting Common Problems

Common issues include abnormal noises, difficulty shifting gears, and clutch failure. Symptoms like grinding sounds or failure to engage gears often indicate worn components. Hydraulic leaks, low fluid levels, or misaligned linkages can disrupt smooth operation. Regular inspections of the clutch, synchronizers, and gear teeth help identify wear early. Addressing these problems promptly prevents costly repairs and ensures reliable performance.

9.2 Maintenance Tips for Longevity

Regular inspection of transmission fluid levels and condition is crucial. Replace worn clutch discs and pressure plates promptly. Lubricate gears and shafts to prevent wear. Check for misaligned components and tighten loose connections. Avoid excessive clutch riding to reduce strain. Schedule professional servicing to ensure optimal performance and extend the lifespan of the manual transmission system.

Manual transmissions are intricate systems requiring precise component interaction to deliver optimal performance, torque, and speed control, making them a cornerstone of automotive engineering and driver engagement.

10.1 Summary of Key Components

The manual transmission system comprises essential components like gears, shafts, clutch, synchronizers, and gear lever. These parts work harmoniously to enable smooth gear shifting, torque control, and efficient power delivery. The clutch connects the engine to the transmission, while gears and shafts manage speed and torque ratios. Synchronizers ensure seamless gear transitions, and the gear lever provides driver control, making manual transmissions reliable and driver-focused.

10.2 The Future of Manual Transmissions

Manual transmissions are evolving with automotive advancements, integrating technology like automated clutch systems and hybrid integration. Despite the rise of automatics, manuals remain popular for their driver engagement and efficiency. Future developments may include advanced materials and smarter gear systems, ensuring manuals stay relevant while adapting to modern demands and environmental standards.