This manual provides comprehensive guidance for installing the Navien NCB-240/130H combi-boiler, ensuring safe and efficient setup. It covers system requirements, installation steps, and essential safety guidelines.

1.1 Overview of the Navien NCB-240/130H Combi-Boiler

The Navien NCB-240/130H is a high-efficiency condensing combi-boiler designed for space-saving installation. It offers simultaneous heating and domestic hot water supply, with advanced features like low emission technology and a user-friendly interface. Its compact design and reliable performance make it ideal for residential applications, providing energy efficiency and consistent comfort.

1.2 Importance of Proper Installation

Proper installation of the Navien NCB-240/130H ensures optimal performance, safety, and longevity. Incorrect setup can lead to inefficiency, increased energy costs, and potential hazards. Adhering to the manual’s guidelines guarantees compliance with safety standards, prevents gas leaks, and maintains warranty validity, ensuring reliable operation and maximizing energy efficiency for years to come.

System Requirements and Considerations

This section outlines essential system requirements, including gas supply, venting, space, and compatibility with existing plumbing and heating systems to ensure optimal installation and performance.

2.1 Compatibility with Existing Plumbing and Heating Systems

Ensure the Navien NCB-240/130H is compatible with your current plumbing and heating systems. Check water pressure, pipe sizes, and existing fixtures to avoid installation issues. Proper compatibility ensures efficient operation and prevents system conflicts, promoting a seamless integration with your home’s infrastructure for reliable heating and water supply.

2.2 Space and Location Requirements

Select a suitable location for the Navien NCB-240/130H, ensuring adequate space for proper installation and maintenance. The boiler must be installed in a well-ventilated area, away from flammable materials. Consider proximity to water and gas lines to minimize piping complexity. Ensure the location complies with local building codes and manufacturer guidelines for optimal performance and safety.

2.3 Venting and Gas Supply Requirements

Ensure proper venting and gas supply for the Navien NCB-240/130H. Use approved venting materials and configurations to meet local codes. The gas supply line must be sized correctly to handle maximum input rates. Ensure the system is vented to avoid confined spaces and meets all safety standards for combustion air and exhaust gases.

Technical Specifications of the Navien NCB-240/130H

The Navien NCB-240/130H is a high-efficiency condensing combi-boiler with advanced features, including precise temperature control and low emissions, ensuring reliable and energy-efficient performance for heating and DHW needs.

3.1 Key Features and Benefits

The Navien NCB-240/130H features high-efficiency condensing technology, reducing emissions and energy costs. Its compact design saves space, while the internal circulation pump and low water cutoff enhance safety and efficiency, ensuring reliable heating and DHW performance.

3.2 Input and Output Capacities

The Navien NCB-240/130H has an input capacity of 240,000 BTU/H and an output capacity of 130,000 BTU/H. These capacities ensure efficient heating and DHW supply, making it suitable for various residential and light commercial applications. The boiler’s high input-output ratio reflects its advanced condensing technology, optimizing energy use for consistent performance and reduced energy consumption.

3.3 Efficiency Ratings and Certifications

The Navien NCB-240/130H boasts high energy efficiency with an AFUE rating of 95%, meeting Energy Star standards. It is certified by organizations such as CSA and DOE, ensuring compliance with safety and environmental regulations. Its condensing technology minimizes emissions, making it an eco-friendly choice for heating and DHW needs, while also reducing operational costs through superior energy utilization.

Pre-Installation Checks

Ensure compatibility with existing systems, verify site preparation, and inspect the boiler for damage. Confirm all components are included and meet local regulations before proceeding with installation.

4.1 Tools and Materials Needed

The installation requires specific tools and materials, including a pressure test kit, gas line connectors, venting components, and safety equipment like gloves and goggles. Ensure all parts are compatible with the Navien NCB-240/130H model and meet local plumbing standards. Refer to the manual for a detailed list to avoid delays during the setup process.

4.2 Safety Precautions and Guidelines

Safety is paramount during installation. Always turn off power and gas supply before starting work. Wear protective gear, including gloves and goggles. Ensure proper ventilation to prevent gas leaks. Follow all local safety regulations and manufacturer guidelines. Only licensed professionals should handle the installation to avoid hazards and ensure compliance with safety standards.

4.3 Local Building Codes and Regulations

Ensure compliance with local building codes and regulations during installation. Obtain necessary permits and inspections to meet safety and efficiency standards. Adhere to regional guidelines for gas and water connections, venting, and electrical systems. Proper compliance ensures safe operation and avoids potential legal issues. Always consult local authorities for specific requirements. Professional installation is recommended for full adherence to regulations.

Installation Steps

Follow detailed step-by-step instructions for unpacking, inspecting, and installing the Navien NCB-240/130H. Ensure proper mounting, leveling, and secure connections for gas, water, and venting systems. Proceed methodically to ensure safety and efficiency.

5.1 Unpacking and Inspection

Carefully unpack the Navien NCB-240/130H boiler and inspect for any visible damage or defects. Check all components, including the burner, heat exchanger, and controls, to ensure they are intact. Verify that all accessories, such as mounting hardware and connectors, are included and properly stored. Refer to the manual for specific unpacking and inspection guidelines to ensure a smooth installation process.

5.2 Mounting and Leveling the Boiler

Mount the Navien NCB-240/130H boiler on a sturdy, level surface to ensure proper operation. Use the provided wall brackets to secure the unit, following the manual’s alignment and leveling instructions. Adjust the boiler’s position as needed to achieve a perfectly horizontal installation, verifying with a spirit level. Ensure all mounting hardware is tightened securely to prevent any movement during operation.

5.3 Connecting Gas and Water Lines

Connect gas and water lines to the Navien NCB-240/130H boiler by following the manual’s specifications. Use appropriate pipe sizes and materials to prevent leaks. Align the pipes correctly and secure all connections tightly. Ensure the system is pressure-tested for leaks before initial operation. Follow safety guidelines to avoid hazards and ensure proper functionality.

5.4 Venting System Installation

Install the venting system according to the manual’s guidelines, using approved materials like PVC or stainless steel. Ensure proper sizing and routing to prevent blockages and leaks. Follow local codes for vent termination locations. Test the system for leaks after installation to ensure safe and efficient operation of the boiler.

Wiring and Electrical Connections

Refer to the wiring diagram for proper connections. Ensure all electrical components are securely linked. Follow safety guidelines to avoid hazards and ensure optimal system functionality.

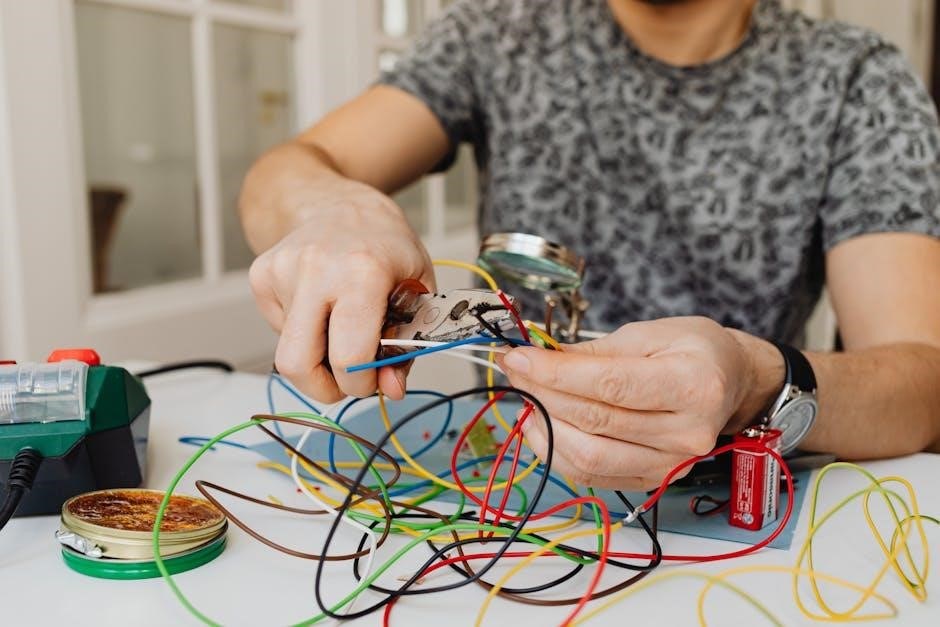

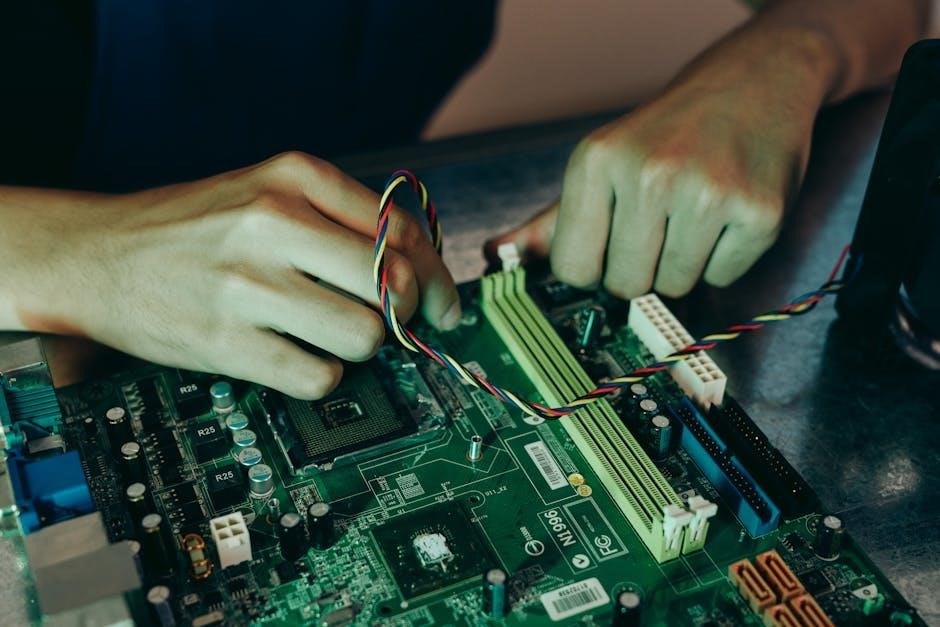

6.1 Understanding the Wiring Diagram

The wiring diagram outlines connections for electrical components. It illustrates circuits for power supply, sensors, and controls. Proper interpretation ensures safe and correct installation, minimizing risks of electrical issues or system malfunctions.

6.2 Connecting Electrical Components

Connect electrical components according to the wiring diagram. Ensure all wires are securely attached to the correct terminals on the circuit board. Connect sensors, pumps, and external controls carefully, following the manual’s instructions. Double-check connections to avoid short circuits or malfunctions. Adhere to safety guidelines to prevent electrical hazards during installation.

6.3 Testing Electrical Connections

After connecting all electrical components, perform thorough testing to ensure proper function. Use a multimeter to check continuity and voltage levels across circuits. Verify that all sensors, pumps, and controls operate as intended. Inspect for any short circuits or open connections. Ensure all error codes are cleared and the system functions without alarms. Document test results for future reference.

Commissioning and Initial Start-Up

This section outlines the process for preparing and activating the Navien NCB-240/130H system, ensuring all components function safely and efficiently upon initial operation.

7.1 Pressure Testing the System

Pressure testing ensures the Navien NCB-240/130H system’s integrity by verifying all connections and components can withstand operating pressure. This step is critical before initial start-up to prevent leaks and ensure safety. The process involves filling the system, checking for any drops in pressure, and verifying that all valves and joints are secure. Always follow the manufacturer’s guidelines to avoid damage or hazards during testing.

7.2 Bleeding Air from the System

Bleeding air from the Navien NCB-240/130H system ensures proper water circulation and efficient heating. Airlocks can cause inefficiency or damage, so this step is crucial. Use the boiler’s built-in air vent or external bleeding valves to remove trapped air. Follow the manufacturer’s instructions to avoid system damage. Repeat the process until water flows smoothly without bubbles.

7.3 Initial Operation and Testing

After commissioning, activate the boiler and verify proper operation. Check for error codes and ensure all functions operate smoothly. Test both heating and water modes to confirm system performance. Follow the manual’s testing procedures to ensure efficiency and safety. Allow the system to run for a short period to verify stability and functionality before full operation.

Maintenance and Servicing

Regular maintenance ensures efficiency, safety, and longevity of the Navien NCB-240/130H. Follow manufacturer recommendations for cleaning, inspections, and part replacements to maintain optimal performance and warranty compliance.

8.1 Recommended Maintenance Schedule

Regular maintenance is crucial for optimal performance. Schedule annual professional inspections, clean filters every 3 months, and inspect heat exchangers and venting systems seasonally. Ensure all components are free from debris and corrosion. Follow the manufacturer’s guidelines for replacement parts and cleaning procedures. Refer to the manual for specific intervals and recommendations to maintain warranty compliance and efficiency.

8.2 Cleaning and Inspecting Components

Regularly clean and inspect the heat exchanger, filters, and venting system to ensure optimal performance. Use a soft brush and mild detergent for cleaning; Inspect for blockages, corrosion, or wear. Replace any damaged parts immediately. Refer to the manual for detailed cleaning procedures and safety precautions to avoid damage or voiding the warranty.

8.3 Troubleshooting Common Issues

Identify common issues like error codes, ignition failures, or water leaks. Check the display for error codes and refer to the manual for solutions. Ensure proper gas supply and venting. Reset the system if necessary. Inspect for blockages or loose connections. Address issues promptly to maintain efficiency and safety. Schedule annual servicing to prevent recurring problems and ensure optimal performance.

Safety Considerations

Gas leaks and emergency shutdowns require immediate attention. Regular inspections ensure system safety. Always follow manufacturer guidelines to prevent hazards and maintain optimal operating conditions.

9.1 Emergency Shutdown Procedures

In case of an emergency, turn off the power supply and gas valve immediately. Close the water inlet and outlet valves. Ensure the venting system is clear. Contact a certified technician for assistance. Regular inspections and adherence to safety guidelines minimize risks and ensure safe operation of the Navien NCB-240/130H combi-boiler.

9.2 Handling Gas Leaks and Other Hazards

In case of a gas leak, immediately turn off the gas supply and power to the boiler. Open windows for ventilation but avoid sparks. Do not operate electrical switches. Contact a licensed technician and emergency services if necessary. Regular inspections of gas lines and connectors can prevent leaks. Always follow safety guidelines to minimize risks and ensure safe operation of the Navien NCB-240/130H.

9.3 Regular Safety Inspections

Regular safety inspections are crucial to ensure the Navien NCB-240/130H operates safely and efficiently. Check gas lines for leaks, inspect venting systems for blockages, and verify electrical connections. Ensure the heat exchanger and combustion chamber are clean. Schedule annual inspections by a licensed technician to maintain performance and prevent potential hazards. This routine helps uphold safety standards and prolongs the boiler’s lifespan.

The Navien NCB-240/130H installation is complete. Ensure all systems function properly, and final checks confirm safety, efficiency, and compliance with guidelines for optimal performance and reliability.

10.1 Verifying Proper Installation

After completing the installation, perform a thorough inspection to ensure all components are correctly connected and functioning. Check for gas leaks using a detector or soapy water, inspect venting for blockages, and verify electrical connections are secure. Test the boiler’s operation, ensuring it heats water and runs quietly. Check system pressure with a gauge and ensure safety mechanisms like emergency shutdown are operational. Document all findings and provide the user with the completed manual for future reference.

10.2 Final Testing and Handover

Conduct a full system test to ensure the boiler operates efficiently and safely. Demonstrate key features and controls to the homeowner, emphasizing energy-saving settings and maintenance tips. Provide all necessary documentation, including manuals and warranty information. Ensure safety features are understood, such as emergency shutdown and leak detection. Confirm that the system meets local codes and standards, completing the installation process smoothly.

References and Additional Resources

Access Navien’s official website for manuals, guides, and technical specifications. Download the Navien mobile app for additional support and resources.

11.1 Manufacturer’s Contact Information

For inquiries or support, contact Navien directly through their official website at www.navien.com. Their site offers downloadable manuals, guides, and technical specifications. Additionally, Navien provides a mobile app for convenient access to resources and support for the NCB-240/130H model.

11.2 Online Support and Manuals

Navien offers extensive online resources, including the official website, where users can download PDF manuals for the NCB-240/130H, such as the Installation & Operation Manual and Quick Installation Manual. The Navien mobile app provides additional support, enabling easy access to guides, troubleshooting, and product specifications, ensuring comprehensive assistance for users and professionals alike.